The automatic Heat Sealer is durable and cost effective

The Dutchpacks Automatic Heat Sealer for composite cans is designed to seal cardboard bases on composite cans by means of effective heat sealing, which ensures a safe and reliable seal every time. The packaging also complies with the new standards and is easily recyclable.

The Automatic Heat Sealer AHS-V1 for composite cans is affordable and features automatic height control with safety protection. The memory functions ensure that the height distance is always 100% in line with the heat seal head.

De automatische Heat Sealer voor composite cans is wasbaar met water aan de binnenkant en beschikt over een afvoersysteem voor het verontreinigde water. Voor extra veiligheid is er een gescheiden gebruik van knoppen en programma’s voor werknemers en technici.

De heat seal kop kan binnen 8 minuten worden verwisseld voor een andere hitte-seal kop.

The Automatic Heat Sealer AHS-V1 is advanced

The Automatic Heat Sealer for Composite Cans uses 4.0 technology and Supervisory Control and Data Acquisition (SCADA) with Linux software.

A machine equipped with SCADA offers numerous advantages. First, real-time monitoring and control allows systems to be continuously monitored and immediately respond to problems, ensuring smooth operation and rapid intervention in the event of disruptions.

In addition, accurate data analysis leads to process optimization, increasing efficiency and productivity. Automation can reduce labor costs and minimize human error, resulting in significant cost savings.

Preventive maintenance is another major advantage; deviations can be detected early, preventing failures and reducing maintenance costs. Data-driven decision-making enables better decisions and process improvements. SCADA systems also improve safety and security by enabling better monitoring and faster response to hazardous situations.

In addition, SCADA offers automatic data recording, which is useful for audits and quality control. The scalability of SCADA makes it easy to add new equipment and sensors. Remote access allows administrators to manage installations remotely, while seamless integration with other business information systems ensures more efficient operations. All these benefits contribute to improved business processes, cost control and operational efficiency.

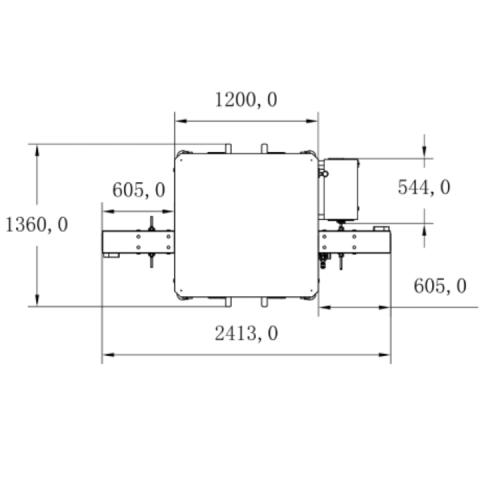

There is a quick release system for the POM star (plastic star) and we use quickly replaceable connectors for all sensors present, which keeps downtime to a minimum. The machine is supplied with an infeed and outfeed conveyor belt of 60cm each (total length per conveyor belt is 1 meter).

The machine is supplied with one complete diameter set. In addition, there is separate speed control for the infeed and outfeed conveyor belt, which contributes to the efficiency of the process, if the outfeed conveyor is full, the machine will no longer accept composite cans for closing. If the outfeed conveyor is empty, the machine will automatically pick up its program again and continue sealing.

The Heat Sealer for composite cans supports a diameter range of 65 to 116 mm and a height range of 80 to 260 mm, if desired we can of course adjust this for you. With a speed of up to 23 per minute and an air pressure of 4 to 6 bar, this device offers efficient performance. The automatic Heat Sealer works on a voltage of 230V, 50Hz and has a power of 1.1 kW.

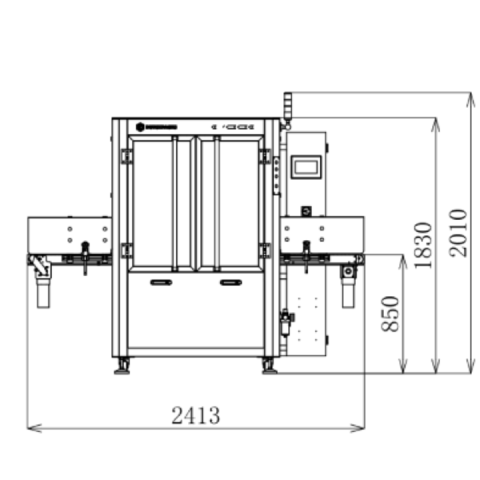

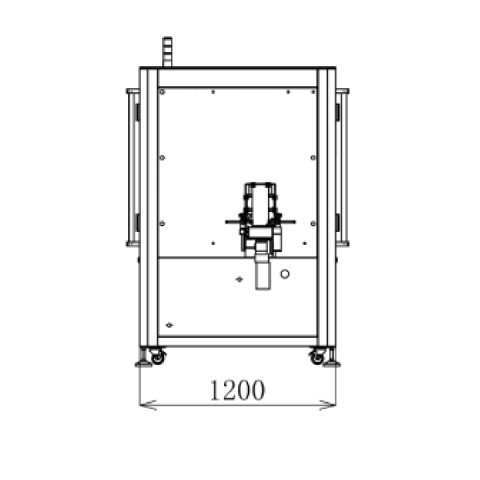

Machine specifications:

| Diameter | 116mm (other diameters on request) |

| Height | 80-260mm |

| Speed | Max. 23 kokers per minute |

| Power supply | 230 Volt / 50Hz / 1,1 kW |

| Dimensions (lxwxh) | 2410x1360x2010mm |

| Input and output conveyor belts | Each 1 meter long, with independent speed control |

| Weight | 630kg |

Additional information:

| Sealing | Tube is stationary during sealing process |

| Compressor | Required (4-6 bar) |

| Air consumption | 5,6 m³ per hour |

| Placement | Dry areas |

| OS | Linux |

| Advanced data and information system | SCADA |

| Quick release system | Included |

| Height adjustment | Automatic |

What is this machine for?

The Automatic Heat Sealer AHS-V1 is suitable for composite cans. Also called composite cans, paper tubes, paper composite cans, composite craft paper can, cardboard tube packaging and kraft paper composite cardboard.

Composite cans are versatile packaging that consist of a combination of different materials, such as cardboard, paper and sometimes metal or plastic. These tubes are often used for packaging a wide range of products, such as food (e.g. chips, powders and spices), household goods and even industrial products. Composite cans are popular because of their durability, light weight and excellent protection of the product against external factors such as light, air and moisture.

Composite can

Heat Sealer AHS-V1 for composite cans is suitable for sealing composite cans.

Dry areas

Heat Sealer AHS-V1 for composite cans can be used in dry areas.

Placement, maintenance & safety

Before the Heat Sealer AHS-V1 for composite cans is delivered to the customer, it undergoes a thorough test with the right material in our workshop at our location in Roosendaal. On request, Dutchpacks can also install the Heat Sealer AHS-V1 for composite cans at the customer’s location and provide extensive guidance on the operation and adjustment of the machine, including information on the associated safety risks.

Dutchpacks guarantees service and maintenance of the Heat Sealer AHS-V1 for composite cans, so you are assured of a device that is always in optimal condition. All components of the Heat Sealer for composite cans are CE-approved, and the product complies with CE regulations.

Standard service

| Certification | CE-certificate |

| Quality control | Included |

| Warranty | 12 months |

| Configuration | Location Dutchpacks |

| Training | Location Dutchpacks |

Optional service

| Placement | Customer location |

| Configuration | Customer location |

| Training | Customer location |

| Service | 24/7 service contract |

| Maintenance | Maintenancecontract |

Picture Gallery

Pictures of Heat Sealer below.

Ask your questions

Hoge Bergen 17

4704RH, Roosendaal

The Netherlands

NL: 0165 397 397

Global: +31 165 397 397

DOWNLOAD DATASHEET

Fill in your email adress and you will receive the data sheet straight into your inbox.