The Heat Sealer has a long lifespan and is financially interesting

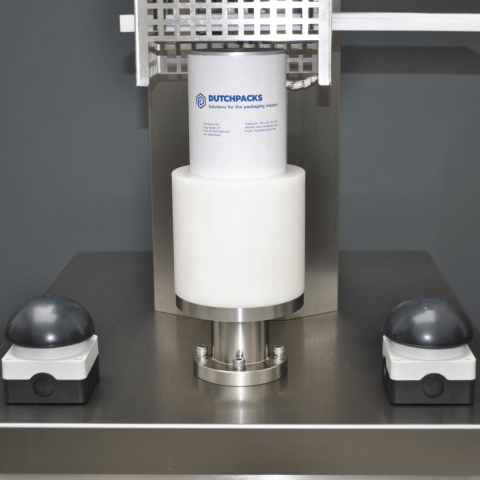

At Dutchpacks we are introducing the semi-automatic Heat Sealer SAHS-116 for composite cans, designed to heat seal cardboard bases on composite cans. The durable stainless steel frame and removable side panels ensure long life and easy maintenance. Our Heat Sealer offers consistent results for closing cardboard, paper and composite tubes and contributes to sustainability by using environmentally friendly cardboard bases.

Heat Sealer for cardboard tubes is advanced and reliable

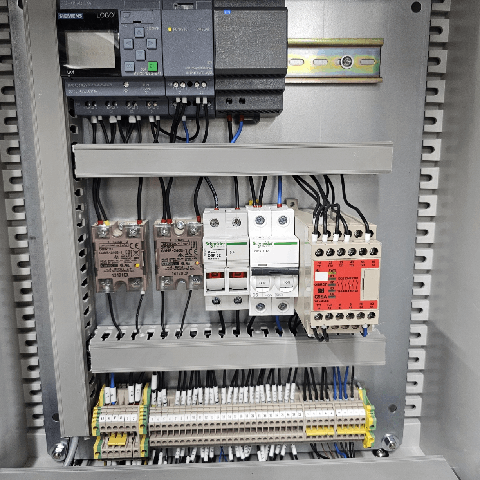

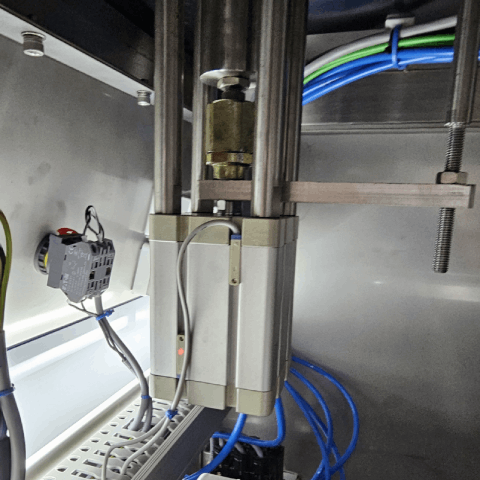

Our advanced technology ensures a perfect seal, with separate adjustable PID controls for optimal temperature control. Safety comes first with Siemens PLC, Eaton buttons and Omron safety sensors, plus an intelligent deactivation program. Suitable for tubes up to 116mm in diameter and up to 240mm high, and adaptable to other sizes. With a speed of 10 per minute, it is perfect for small-scale, precise use. This machine is ideal for small companies.

Thanks to the Omron Solid State Relays, there is reliable temperature control in the machine. The Heat Sealer is also easy to move by means of a set of adjustable feet that are on the machine. This provides a possibility to adjust the machine to the correct height.

Machine specifications:

| Diameter | 116mm (other diameters on request) |

| Height | 60-240mm (additional height on request) |

| Speed | Up to 10 tubes per minute |

| Power supply | 230 Volt / 50Hz / 0,8 kW |

| Dimensions (lxwxh) | 693x574x1800mm |

| Weight | 135kg |

Additional information:

| Sealing | Tube is stationary during sealing process |

| Compressor | Required (4-6 bar) |

| Air consumption | 32 l/m |

| Placement | Dry areas |

| Cooling system | Included |

What is this machine for?

The Heat Sealer SAHS is suitable for cardboard tubes. Also called composite cans, paper tubes, paper composite cans, composite craft paper can, cardboard tube packaging and kraft paper composite cardboard.

Composite cans are versatile packaging that consist of a combination of different materials, such as cardboard, paper and sometimes metal or plastic. These tubes are often used for packaging a wide range of products, such as food (e.g. chips, powders and spices), household goods and even industrial products. Composite cans are popular because of their durability, light weight and excellent protection of the product against external factors such as light, air and moisture.

Composite cans

Heat Sealer SAHS is suitable for sealing composite cans.

Dry areas

Heat Sealer SAHS can be used in dry areas.

Placement, maintenance & safety

Before the Heat Sealer SAHS is delivered to the customer, it undergoes a thorough test with the right material in our workshop at our location in Roosendaal. On request, Dutchpacks can also install the Heat Sealer SAHS at the customer’s location and provide extensive guidance on the operation and adjustment of the machine, including information on the associated safety risks.

Dutchpacks guarantees service and maintenance of the Heat Sealer SAHS, so you are assured of a device that is always in optimal condition. All components of the Heat Sealer are CE-approved, and the product complies with CE regulations.

Standard service

| Certification | CE-certificate |

| Quality control | Included |

| Warranty | 12 months |

| Configuration | Location Dutchpacks |

| Training | Location Dutchpacks |

Optional service

| Placement | Customer location |

| Configuration | Customer location |

| Training | Customer location |

| Service | 24/7 service contract |

| Maintenance | Maintenance contract |

Picture Gallery

Pictures of Heat Sealer below.

Ask your questions

Hoge Bergen 17

4704RH, Roosendaal

The Netherlands

NL: 0165 397 397

Global: +31 165 397 397

DOWNLOAD DATASHEET

Fill in your email adress and you will receive the data sheet straight into your inbox.